trailer trucks have become vital in modern cargo transport, capable of handling heavy loads not just on highways but also on congested city routes. The arrangement of the axles plays a big role in their strength, efficiency, and safety. Hence, it is quite common for people to ask the question: how many axles does a semi truck have?

The answer to it is not the same in all situations as different factors like the truck design, the axle configurations, axle types, cargo capacity, and weight regulations determine it.

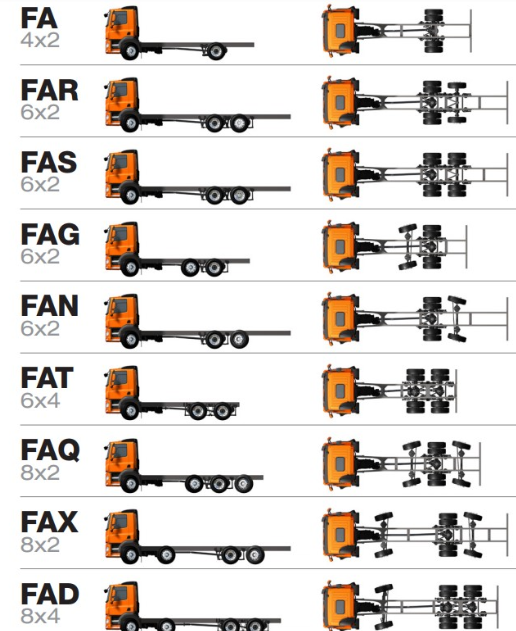

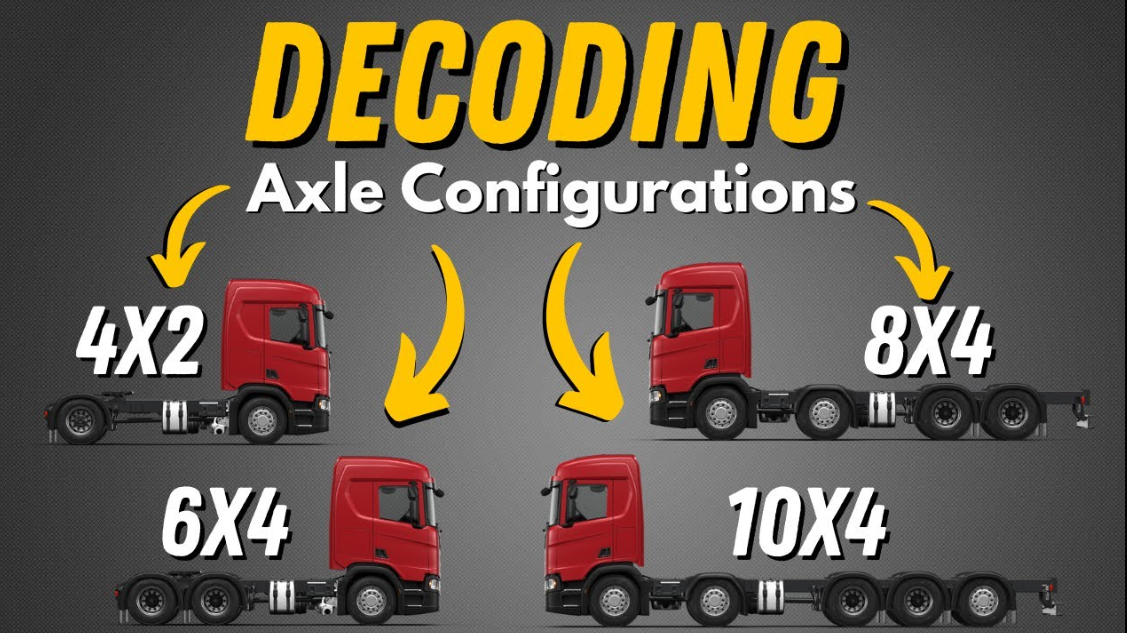

The basic 4×2 setups to the advanced multi axle configurations with tandem axles and lift axles are examples of how the design affects the truck’s performance and compliance. Fleet managers, drivers, and all those who are working with heavy-duty trucks must be acquainted with these arrangements.

The Complex Truck Configurations “YOU NEVER” Heard Of

The Most Common Semi Truck Axle Configurations

Axle configurations are not simply a question of how many there are they also affect factors like payload capacity, traction, and safety. Below are the types that are mostly used:

4×2 Configuration

The 4×2 configuration is the most typical pattern found in tractor units and trailer trucks. It includes a steering axle and a drive axle, making it suitable for light cargo and short trips.

This type is advantageous as:

- It consumes less fuel because of the fewer axles it has.

- Maintenance is easier — fewer moving parts mean easier maintenance.

- This type is ideal for urban transportation with lower gross vehicle weight ways.

The big disadvantage here is that having just a steering axle and a drive axle makes this configuration unable to transport heavy or long-distance goods.

6×2 Configuration

The 6×2 axle configuration is one of the latest innovations, which includes one steering axle, one powered drive axle, and a third axle, which is usually a tag axle or lift axle. This design helps to balance the axle load and to increase the cargo capacity as well.

- They are mostly found in regional delivery trucks where the requirement is moderate payload capacity.

- The lift axle raised reduces tire wear.

- It provides better compliance with road weight limits as compared to 4×2.

However, with only one powered drive axle, traction issues may arise on rough terrain.

6×4 Configuration

The 6×4 configuration is the most popular one among heavy trucks and, therefore, has one steering axle and two drive axles together providing more traction and durability.

- Longest & heavy weights are gross combination weights, which also handle long-haul & interstate freight.

- It works well, especially in the hilly, snowy, or unpaved road conditions.

- Truck stability and safety under heavy loads is the primary reason fleets prefer this kind.

- The vehicle is benefitting from safety features however, this increases fuel consumption.

Specially Designed Axle Configurations

In addition to the regular axle configurations, some additional specialized configurations come in for improvements in load distribution and road safety.

Lift Axles

Lift axles can be lifted or dropped based on cargo weight.

- Lifted: They increase tire wear, but improve fuel efficiency.

- Multi axle configurations are essential because of their flexibilities, which can be among the operators without being a permanent increase in maintenance.

Triple Axles

Triple axles or tridem axles are a combo that has three grouped axles together, most often on the trailer axles.

- Improves load distribution across multiple axles.

- The higher payload capacity without violating the road weight limits is achievable.

- The greater vehicle stability is a benefit with oversized or bulk loads.

In specialized areas like construction, mining, and heavy logistical work, this is frequently a choice.

Merits of Having Multiple Axles

Better Weight Distribution

The more axles used, the better load per axle management available. For example, a five-axle configuration makes sure the weight is appropriately spread, which helps in keeping each axle under its own axle weight rating.

More axle spacing prevents infrastructure damage and gives longer suspension type life. Fleet operators often reference an axle configuration guide to ensure compliance and efficiency.

Enhanced Safety and Stability

Stability in trucks is inevitable because of the risk of roll-overs and accidents. The added axles mean:

- Better vehicle balance in braking.

- Safer turns due to axle alignment and dual steering axles.

- Road safety through fewer blown tires.

Technicalities like independent suspension or rigid axles are factors that affect truck performance under heavy loading conditions.

Weight Regulations Adherence

Every country has rules about gross vehicle weight and axle load ratings that drivers must adhere to. Having a multi-axle design, they get to:

- Meet the legal axle limits.

- Have better truck performance with no fines.

- Remain efficient in junction and highway axle setups along the highways for long-haul drives.

This is the reason a four-axle configuration or even a multi-axle configuration is the most common in today’s fleets.

Axle Configuration Comparison Table

| Configuration | Axle Setup (Steering/Drive) | Typical Use Cases | Pros | Cons |

| 4×2 | 1 steering / 1 drive | Light loads, urban delivery | Fuel efficient, low maintenance | Limited load capacity, less traction |

| 6×2 | 1 steering / 1 drive / 1 tag | Regional freight, medium loads | Good balance, reduced tire wear | Lower traction on rough terrain |

| 6×4 | 1 steering / 2 drive | Long-haul, heavy loads, rough roads | Excellent stability & traction | Higher fuel consumption |

| Lift Axles | Variable additional axles | Flexible loads, variable cargo | Adjustable, improves compliance | More complex systems |

| Triple/Tridem | 3 grouped trailer axles | Bulk haul, construction, mining | High payload capacity, even distribution | Increased tire and maintenance costs |

Real-World Examples

- The tandem axles and even the tandem axle count are integrated into the design of the North American trailer trucks, giving the long-distance transport and the law-conforming aspect a good balance.

- Tridem axles are mostly found in Canadian logging trucks due to the high payload capacity that the axles can carry and the stricter laws governing axle distribution.

- Lift axles are quite popular in European fleets where road weight limits are very tight, and flexibility is crucial.

- Specialized haulers may engage with dual steering axles and tag axles for oversized products, as well as for urban maneuvering.

These distinctions illustrate that altering the axle systems can change not only what is good for technical measurements but also what is useful for business operations and law compliance.

Recap

So thus, how many axles are there in a semi truck? The answer to it is based a lot on the axle configurations, the trailer axle count, and the gross combination weight.

The setups may vary from a basic 4×2 tractor unit to a five-axle configuration having both tandem and tridem axles, where every assembly balances the cargo space with truck stability and restrictive legal axle limits.

Along with axle types, spacing, and axle distribution guides, understanding them enables operators to maximize the performance of trucks and stay compliant with road regulations.

For fleet owners, the choice of a multi axle configuration is not just about making sure the trucks are under weight limits. It’s about the road safety aspect, vehicle stability improvement, and optimized payload capacity for the top logistics environment.